By TIM COOK

The Journal

HARPERS FERRY, W.Va. — A new employer is coming to town and will be looking for a few workers.

Offering considerable specialized training, those jobs will include about 30 managers and supervisors as well as about 120 front-line skilled trade workers, some of whom will run highly specialized machines.

Among the other factory floor jobs it will bring to Jefferson County, Roxul will hire electricians, millwrights and people to operate forklift machines.

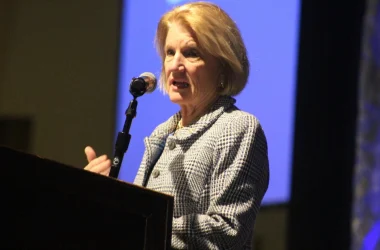

“We’ll be looking in the new year to host some job fairs,” said Leslie McLaren, a communications and government affairs manager for Roxul, a Danish company that produces durable insulation from molten rock.

“There’s a lot of opportunity,” she said.

McLaren and a Roxul vice president, Peter Regenberg, discussed the company’s plans in the Eastern Panhandle during a Jefferson County Chamber of Commerce meeting Thursday at the Clarion Inn, in Harpers Ferry.

Roxul is looking to hire new workers to begin training them for its Ranson manufacturing plant sometime in 2019, McLaren said. The plant is scheduled to fully operate during the first quarter of 2020, where it will be turning out residential and “stone wool” insulation products for distribution and sale.

The company plans to conduct its own job fairs in and around Jefferson County, McLaren said.

“Certainly, when we do (hire workers), it will be fast and furious,” she added.

Across North America and Europe, Roxul, which operates as the Rockwool Group outside of the United States, employees 11,000 people and generates $2.3 billion in sales. The company started in Denmark in 1937 and sells its products widely across Europe.

“Now the focus (for the company’s future sales growth) really is on our North American operations,” Regenberg said.

Roxul currently operates plants in Mississippi, and in British Columbia and Ontario in Canada.

Its new Ranson plant will be located at the former Jefferson Orchards site adjacent to W.Va. 9. To serve customers in the Northeast, the company plans to open with three shifts of workers to operate the new plant 24 hours a day.

Central to the plant will be a furnace that will heat mined rock–essentially basalt and slag material–to 3,000 degrees Fahrenheit to shape and mold the material into fibrous insulation.

“Our business is to melt rock and turn it into insulation,” Regenberg said. “It’s literally lava from a volcano–that is what comes out” of the company’s furnaces.

Roxul’s special-formula insulation and sound-dampening products for homes, commercial buildings and boats provide excellent fire resistance, Regenberg said. Its plants also recycle about 40 percent of the water and other materials they use for its manufacturing process, he pointed out.

Regenberg said Roxul settled on opening a new plant in Ranson because, in part, of the availability of skilled, conscientious labor in the area. But the company is willing to teach skills and jobs to people with the right work ethics, McLaren and Regenberg said.

“It’s mostly, for me, a question of finding people with the right mentality–a sense of urgency, a proactiveness in your mindset,” Regenberg said. “If you have that culture, we will train you.”

Regenberg said Roxul officials carefully considered the available workforce in the Jefferson County area, a process that included interviewing local community college officials as well as human resource managers at other manufacturing companies in the area.

“We have done a lot of research,” he said. “We don’t take a chance on this, because the availability of the local workforce is key. There’s no point in spending $150 million and then you have an empty factory that no one is there to run.”

Regenberg said initial training takes about six to 10 weeks for a new Roxul worker to become skilled in the basics of operating and overseeing the company’s machines, which includes robotics arms that automatically lift and wrap products and materials. However, it also can take a year and a half for a worker to proficiently operate some machines.

McLaren described Roxul’s employee training as “very intense,” a process that could involves months. “We’re training for not only the technology and the process–the safety is number for us,” she said. “So it’s important to have everybody online and working together.”

Many workers at the new Ranson plant will be trained by the company’s current employees at its different plants, McLaren said. “For a lot of the hourlys (workers), we’ll provide the training,” she said.

Depending on the job they are hired to perform, workers might visit plants in Mississippi, Canada or Europe during their training, she added.

McLaren pointed out that she has worked for Roxul for 17 years. “People come and they tend not to leave,” she said. “We treat our employees well, fairly.”

See more from The Journal